Tyne Gangway and Dutch Safeway sign a Co-operation Agreement.

News & Press

Tyne Gangway’s Managing Director James Russell: “Tyne Gangway is perfectly located to provide local services to the Port of Tyne and the wider UK now offering the services of the Van Aalst Group of companies…

Tyne Gangway after-sales services

News & PressIt is recommended that all Gangways and Accommodation ladders should meet IMO 1331. To meet this they should be inspected annually and load tested 5-yearly.

• Accommodation ladders to ISO 5488 Ships and marine technology

• Gangways for…

Gangway Stock for Hire!

News & PressTyne Gangway supplies a wide range of marine access equipment including, aluminium gangways; SIS7 bulwark ladders, and lifting slings from stock, which are readily available to hire (longterm or short) or purchase, we also stock a suitable range…

Dolphin Walkways

News & PressRecently, Tyne Gangway saw the load-out of 6 aluminium pedestrian dolphin access bridges, ranging from 25-40m long. For further information or if you have a requirement for this type of bridge, please contact us on 0191 2623657 or email inf…

https://www.tynegangway.com/wp-content/uploads/2020/08/james-russell-1.jpg

258

258

redman

https://www.tynegangway.com/wp-content/uploads/2018/08/tyne-gangway-300x106.png

redman2020-08-10 10:50:382023-11-21 14:08:57Tyne Gangway would like to welcome and introduce James Russell as Managing Director.

https://www.tynegangway.com/wp-content/uploads/2020/08/james-russell-1.jpg

258

258

redman

https://www.tynegangway.com/wp-content/uploads/2018/08/tyne-gangway-300x106.png

redman2020-08-10 10:50:382023-11-21 14:08:57Tyne Gangway would like to welcome and introduce James Russell as Managing Director.

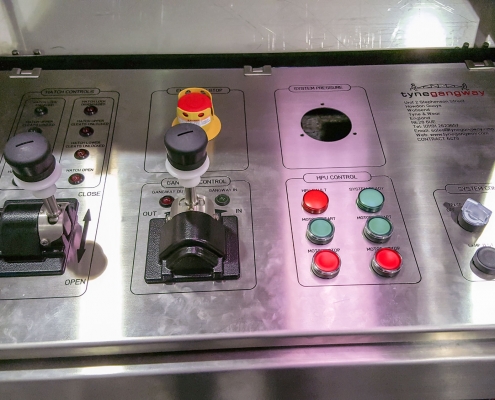

Hydraulic deployed telescopic gangway movie

News & Presshttps://www.youtube.com/watch?v=6NgDQRfaS5s

View our latest 3d render of our Hydraulic deployed telescopic gangway

For more information on our gangways available from Tyne Gangway.

Emergency escape slide simulator for use at Chicago airport

News & PressTyne Gangway have secured an order to design and build an emergency escape slide simulator for use at Chicago airport. The slide will be used for fire evacuation training at the airport and will simulate the function of the inflatable slides…

Marine access systems: finding a safe solution

News & PressThe variable and constantly moving gap between a marine vessel and the jetty or dock is an interesting problem.

Normally, the ship is at port to load or unload cargo, passengers or liquids. It is therefore reasonable to assume that the height…

Gangways for the Tall Ships Regatta

Events, News & PressTyne Gangway have agreed to loan (FOC) the Port of Sunderland several gangways for the duration of the Tall Ships Regatta

Great to meet with Ken McDonald, Managing Director @tynegangway who will be providing the gangways for some of The Tall…

Tyne Gangway despatch fully automated Forward Operational Deployment System (F.O.D.S) for the Australian Antarctic Supply Research Vessel

News & PressThe 160-metre ASRV will perform numerous tasks for the Australian Antarctic Division (AAD). “The new vessel is a multi-mission ship designed to sustain geographically dispersed stations, support helicopter operations, sustain shore parties…